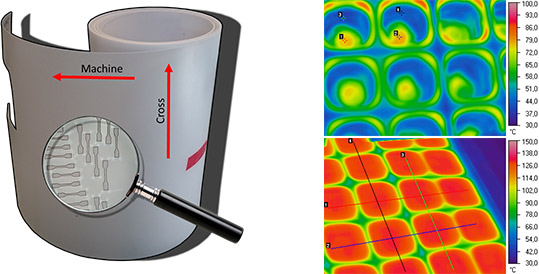

Case Study: Machine / Material interaction

Challenge: Can we help uncover why plastic cups formed from one supplier’s roll stock performed differently from another on the same machine?

Pack 3.0 Solution: A client was running a FFS (Form Fill Seal) thermoforming line with plastic material from two different suppliers. Both suppliers claimed the same specs, but the final cups didn’t have the same properties.

Thanks to our unique thermoforming pilot machine, we were able to replicate the capabilities of each supplier’s plastic sheet.

A detailed scientific audit revealed which supplier really met specifications and how they could be improved overall. The new specifications, along with new thermoforming guidelines, helped to significantly increase the line performance.

Timeframe: 3 months

Our client: “The main advantage of working with Pack 3.0 is their full knowledge about BOTH packaging material science and digital simulation.”

Share: