Our experienced and visionary engineers use digital simulation technology pioneered by the aerospace industry to help companies explore an unlimited variety of innovative packaging solutions. The result is packaging that works incredibly and looks beautiful while cutting waste, lowering cost and speeding time to market.

VIRTUAL DESIGNS.

REAL WORLD BENEFITS..

With digital simulation, we can subject your packaging to a vast range of real world tests to guarantee they’ll function properly and stand up to the rigors found at all stages of the product’s lifecycle.

With digital simulation, we can subject your packaging to a vast range of real world tests to guarantee they’ll function properly and stand up to the rigors found at all stages of the product’s lifecycle.

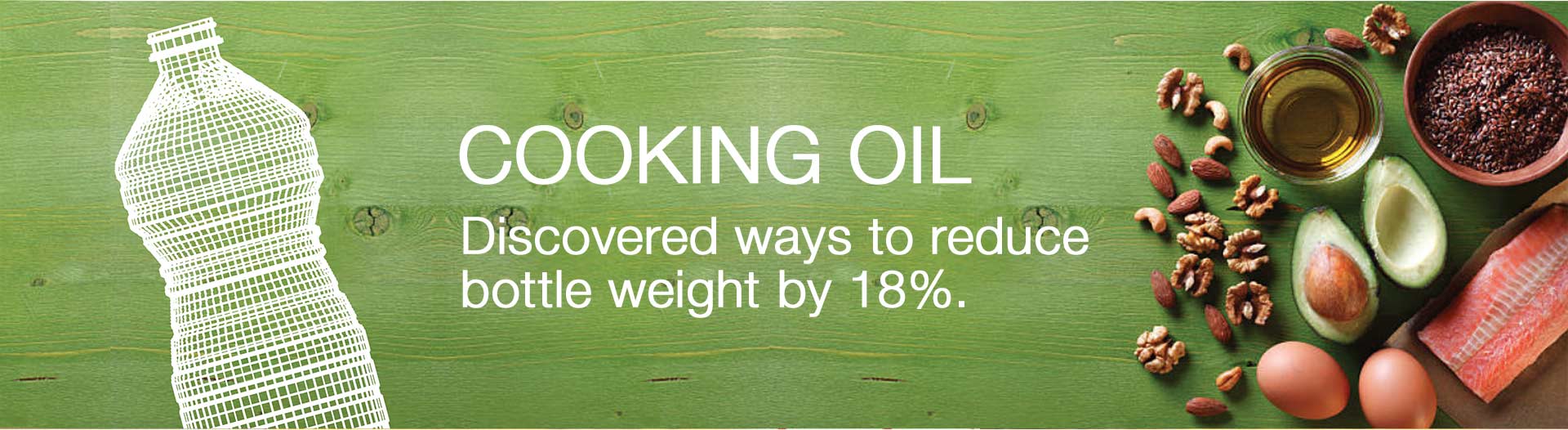

As one example, our designs currently help clients save more than 1,000 tons of plastic material a year. Even a slight reduction can mean substantial savings in raw materials and shipping costs.

As one example, our designs currently help clients save more than 1,000 tons of plastic material a year. Even a slight reduction can mean substantial savings in raw materials and shipping costs.

Together we can discover and explore many ways to reduce your product’s environmental impact: lightweighting, using more recyclable materials, optimizing logistics and using less energy in the manufacturing process.

Together we can discover and explore many ways to reduce your product’s environmental impact: lightweighting, using more recyclable materials, optimizing logistics and using less energy in the manufacturing process.

Creating and testing accurate virtual designs is much quicker than building physical models, so you can be on shelves sooner.

Creating and testing accurate virtual designs is much quicker than building physical models, so you can be on shelves sooner.

Digital simulation lets you explore and test more designs without the cost of building physical prototypes.

Digital simulation lets you explore and test more designs without the cost of building physical prototypes.

Ensure your customers’ happiness by maximizing a product’s appearance, ergonomics, ease of use and functionality.

Ensure your customers’ happiness by maximizing a product’s appearance, ergonomics, ease of use and functionality.

With the ability to explore more options virtually, your designers can push the envelope on what packaging can be, resulting in truly eye-catching and memorable designs.

With the ability to explore more options virtually, your designers can push the envelope on what packaging can be, resulting in truly eye-catching and memorable designs.

Predict and prove how a package will function and meet the quality standards even before the prototype is made.

Predict and prove how a package will function and meet the quality standards even before the prototype is made.

Ensure your innovations will hold up throughout production from manufacturing, filling and conveying through stacking, pallet transporting and shelf stability.

Ensure your innovations will hold up throughout production from manufacturing, filling and conveying through stacking, pallet transporting and shelf stability.

“Digital simulation technologies require strong competencies and need to be managed in a restless way. We, at Danone, use such skills for more than 15 years & doing so now in collaboration with Pack 3.0 helps us to move from Good to Great packaging design.”

Frédéric J., Director,

Plastic Material Technology Center, DANONE

“Thanks to great simulation tools, and their unique expertise, the Pack 3.0 team has a real added value to tackle all the challenges that L’Oréal has to face in terms of agility and time to market.

Luc M., Head of Packaging Design, L’OREAL

“Pack 3.0 offers a very rare combination of packaging engineering knowledge together with the mastery of the most advanced simulation tools provided by Dassault Systèmes. This creates a lot of value for our clients, and we are delightful to collaborate with such a great team.”

Philippe L., Vice President Consumer Goods, Consumer Packaged Goods & Retail, DASSAULT SYSTÈMES

“Serge is like my ‘pocket Einstein’. When I have a problem he finds a solution… And the team at Pack 3.0 is very friendly, calm and open to trying new things. They always say ‘we accept the challenge’.”

Andrea A., Associate ITQ Manager, GENERALS MILLS

“The main advantage of working with Pack 3.0 is their full knowledge about both packaging and digital simulation technology.”

Damien L.B., Packaging Development, YVES-ROCHER